We invite you to visit our ticket printing workshop and see how we produce our short runs of Edmondson style tickets

1. Receive and agree the customer's order

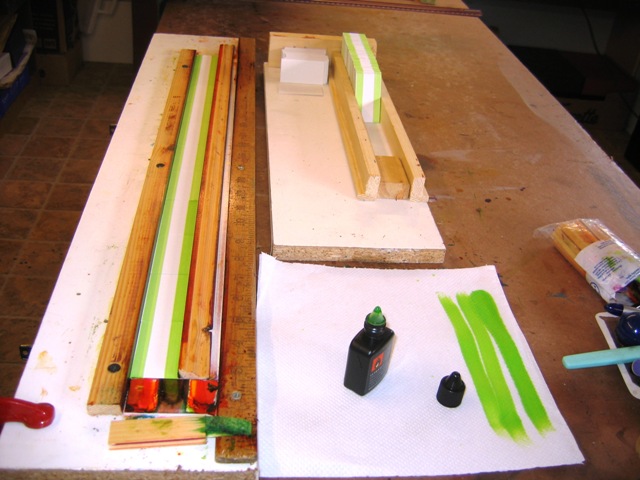

2. Prepare the blank cards: here we see horizontal stripes being added using the felt nib in the foreground.

3. Most of our tickets are produced from monotype, that is individual letters, number and symbols but we also use linotype, that is a whole line cast in one piece, for words we use frequently such as the names of the stations on the Talyllyn Railway or plates which are supplied commercially for tickets we supply regularly.

4. We use a small forme just larger than the size of a ticket which is then fitted inside the larger forme on the machine.

5. The type is kept loose while it is set and then tightened up using an Allen key and grub nuts.

6. There are three grubs screws to tighten, one on the end and two on the side: the type is then held tightly in place during printing.

7. The small forme is now held securely in the larger machine forme.

8. The Adana machine ready for action, with the forme in place and the platen inked up ready to take a few runs for a final check of the spellings, spacing, alignment and so on. We are careful to keep the alignment of the forme and the printing surface the same to avoid wasting time making more adjustments than necessary.

9. With the final checks completed it is time to go into production.

10. A hundred tickets are soon produced and kept in groups of tens and fifties for a few minutes while the ink dries.

11. The tickets are collected in fifties ready for numbering.

12. When the printing session is over, the forme is removed and the surplus ink cleaned off the rollers and platen.

13. For good results it is essential that the type is kept clean so solvent is applied and the type cleaned with a stiff brush to avoid any build-up of dried ink. The individual pieces are then returned carefully to the correct box to avoid getting the different fonts and sizes mixed.

14. Now the platen receives attention: it is then removed and the moving parts on the machine are lubricated.

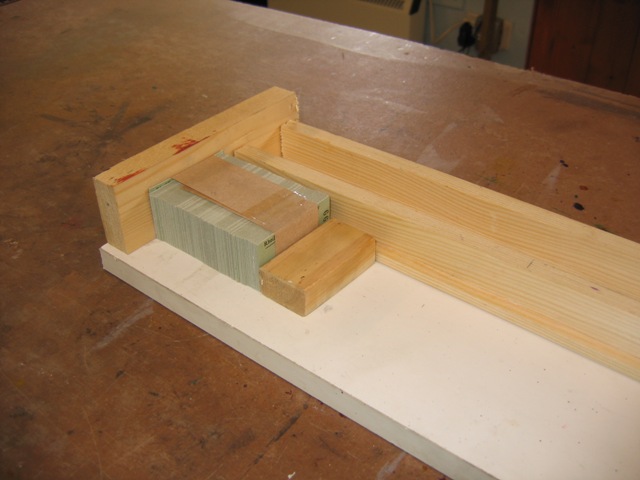

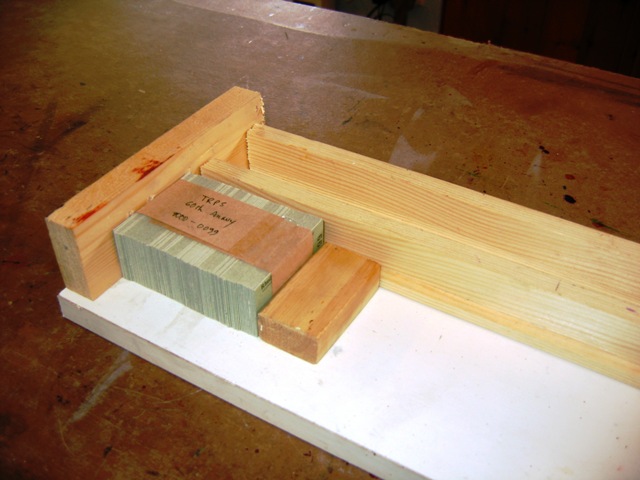

15. The tickets are numbered using an automatic numbering machine and a simple jig in which each ticket is located in turn. We have machines that offer a variety of styles of numbering, normally in four figures, although we can use three figures or even two for very short runs.

16. At this stage is in imperative that the tickets are kept the correct order, either in railway style which are issued from the bottom of the stack or in tramway style if the tickets are to be issued from the top. A simple rack with a loose stop assists in this process and also enables the tickets to be kept neatly together.

17. The order is then bundled tightly together.

18. Finally the tickets are labelled and sent out to the customer.